Press Releases

CSeries tests further validate aerodynamic design & support fuel efficiency projections

Today, Bombardier Aerospace confirmed that final results of a three-phase wind tunnel test program provided further validation of the CSeries aircraft’s aerodynamic design. They also support design predictions that the CSeries aircraft, optimized specifically for the growing 100- to 149-seat market, will deliver a step-change in fuel efficiency. The wind tunnel tests also contributed to the achievement of optimal integration of Pratt & Whitney’s ultra high-bypass ratio (12:1) PurePower® PW1500G engine.

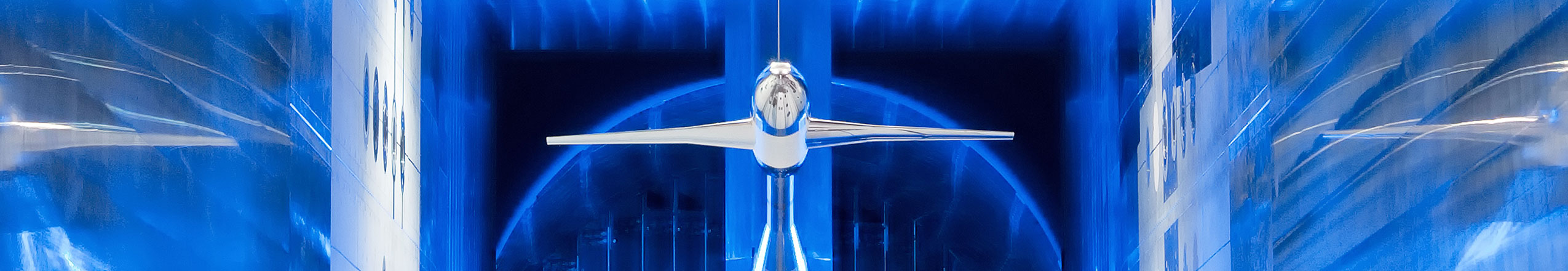

CSeries aircraft wind tunnel model undergoing high-speed tests at ETW. Photo: © ETW.

Initiated more than five years ago, during the early stages of the CSeries aircraft’s conceptual design, the wind tunnel test program progressed through the aircraft’s subsequent definition and detailed design phases.

Validation of the CSeries aircraft’s aerodynamic design included extensive use of state-of-the-art Computational Fluid Dynamics (CFD), made possible through the use of contemporary super-computers that are significantly more capable - and 100,000 times faster - than computers available when the aircraft currently serving the 100- to 149-seat market were designed. These tools permitted the minimization of interference drag and also facilitated the design of the engine nacelle and thrust reverser.

To simulate actual flying conditions, the wind tunnel tests were conducted with over 20 sophisticated scale models over more than 4,500 testing hours at facilities in Canada, France, Germany, the Netherlands, the United Kingdom and the United States.

“Simulated conditions during the wind tunnel tests closely correlate to real world flying conditions and the resulting data were used to improve and validate final CSeries aircraft design and systems,” said David Tidd, Vice President, CSeries Integrated Product Development, Bombardier Commercial Aircraft. “This latest achievement for the CSeries aircraft represents the most extensive and complex wind tunnel testing that Bombardier has ever conducted; it marks another key advance in the jetliner’s development.”

The scale models of the CSeries jetliner used in the testing were equipped with precise instrumentation to measure air flow, including as many as 700 pressure-sensitive ports over the wings, fuselage and tail. The models included moving parts, such as wing flaps and leading edge slats, which could be repositioned to reflect actual flying events. Some models were equipped with miniature air-driven turbine engines to gauge the air flow interference with the aircraft wings. The largest of the models, at 13.7 per cent scale, had a wingspan of approximately 4.5 metres (15 feet).

Using the scale models and the environmental conditions possible in the wind tunnels, Bombardier engineers were able to simulate the aerodynamics of the CSeries aircraft in various flight scenarios such as landing, take-off and cruising at high altitudes.

The CSeries aircraft family will offer a 15 per cent cash operating cost advantage and a 20 per cent fuel burn advantage; greatly reduced noise and emissions; as well as superior operational flexibility, exceptional airfield performance and a range of 2,950 nm (5,463 km). It will also provide passengers with widebody-style seating in a single-aisle aircraft.

Bombardier has booked firm orders for a total of 133 CSeries aircraft, including 61 CS100 and 72 CS300 aircraft. The CSeries aircraft program has also booked options and purchase rights for an additional 129 aircraft.

Background

ETW - Pushes the Limits

Wind tunnels, using scaled down aircraft models, are the major source of aerodynamic design data for new aircraft projects. Wind tunnels are indispensable tools for aerodynamic research and aircraft development; they complement and validate flow simulation methods on the most powerful computers.

ETW, the European Transonic Wind Tunnel, was designed and constructed by the four European countries France, Germany, United Kingdom and The Netherlands. It is operated based on a non-profit policy by the ETW GmbH, founded in 1988. Its location in Cologne, Germany, is right in the middle of Europe.

European researchers and engineers harness ETW’s capabilities for advancing aeronautical science into aircraft innovation by accessing real-flight conditions in this cutting edge ground-test laboratory.

ETW is the worldwide leading wind tunnel for testing aircraft at real flight conditions. Aircraft performance and their flight envelope limits can be accurately determined with unique quality at ETW long before flight testing of a first prototype. This enables significant reductions in the technical and economic risks associated with the development of new aircraft. Manufacturers from all over the world take advantage of the exceptional features of this high-tech facility enhancing the performance, economic viability, and environmental friendliness of their future aircraft.

ETW – Erweitert Horizonte

Aerodynamische Entwurfsdaten für neue Flugzeugprojekte werden zu einem großen Teil aus Windkanaluntersuchungen an maßstäblich verkleinerten Flugzeugmodellen gewonnen. Windkanäle sind unverzichtbare Werkzeuge sowohl für die Strömungsforschung als auch für die Flugzeugentwicklung; sie ergänzen und validieren Verfahren zur Strömungssimulation auf modernsten Hochleistungsrechnern.

Der Europäische Transschall-Windkanal ETW ist eine transnationale Forschungseinrichtung in Köln. Er wurde von den vier Staaten Frankreich, Deutschland, Großbritannien und den Niederlanden entwickelt und gebaut. Betrieben wird er von der ETW GmbH, die als eigenständiges Non-Profit-Unternehmen 1988 gegründet wurde.

Der ETW erlaubt europäischen Forschenden und Ingenieur:innen, tatsächliche Flugzustände unter Laborbedingungen am Boden darzustellen, um wissenschaftliche Erkenntnisse zu erarbeiten und in Luftfahrtinnovationen zu überführen.

Der ETW ist der weltweit führende Windkanal, in dem Luftfahrzeuge unter wirklichkeitsgetreuen Flugbedingungen getestet werden können. Lange bevor der erste Prototyp für einen Flugtest zur Verfügung steht, können im ETW die Leistungsfähigkeit und die Flugbereichsgrenzen eines Neuentwurfs genauestens und mit einzigartiger Qualität bestimmt werden. Dies reduziert erheblich die technischen und wirtschaftlichen Risiken, die mit der Entwicklung neuer Luftfahrzeuge verbunden sind. Hersteller aus aller Welt nutzen die außergewöhnlichen Möglichkeiten dieser Hightech-Einrichtung, um die Leistungsfähigkeit, die Wirtschaftlichkeit und die Umweltfreundlichkeit ihrer zukünftigen Produkte nachhaltig zu verbessern.