Press Releases

LuFo V-3 LoCaRe

Modern aircraft should not only fly climate friendly but also quietly. Researchers and developers use the cryogenically operated ETW to drive innovations and optimise new, lighter designs in real flight conditions at model scale. Thanks to LuFo V-3 LoCaRe in cooperation with Embraer, sound sources during take-off and landing can now be measured and improved in parallel with flight performance data in the ETW using aeroacoustic measurement technology developed by DLR.

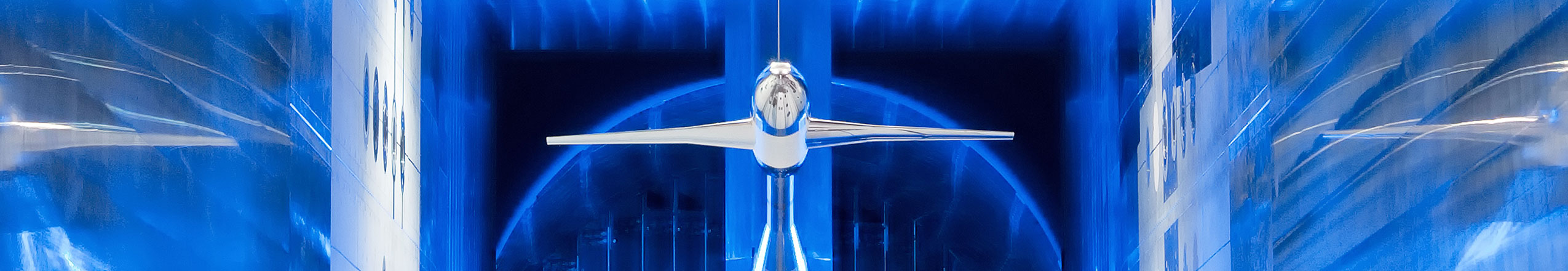

Embraer´s full-span model and a DLR microphone array in the bottom wall of ETW’s slotted test section. Photo: © DLR/ETW.

For the first time, DLR successfully performed acoustic measurements on a Embraer full-span model at flight-relevant Mach and Reynolds numbers piggyback to performance tests in ETW thanks to co-funding from the German LuFo V-3 project LoCaRe “Localisation and Characterisation of Flight Relevant Noise Sources on High Lift Systems”.

A preceding investigation within the LuFo IV project ALSA “Acoustic Localisation of Flow Separation in ETW” had demonstrated the applicability of microphone array measurements under cryogenic conditions for half-span models in a closed-wall test section configuration. Here, this method was improved and extended for the application to full-span models in a slotted test section configuration. For this purpose, an arrangement of 96 microphones in the wind tunnel bottom wall was implemented to achieve an optimal spatial resolution of potential noise sources in the relevant frequency range. Considering existing observation windows, pressure tappings and slots in the walls of the ETW test section, dedicated inserts have been installed, which were made of cryogenic-proof Obo-wood with flush mounted microphones suitable for cryogenic and pressurised environment. In order to understand the physics of the identified noise sources, time-synchronised PIV measurements were performed at the flap side edges for selected data points.

The measurement programme included low-speed measurements in the Mach number range between 0.20 and 0.30 and at Reynolds numbers between 3 and 10 million. The full-span model provided by Embraer was equipped with nacelle-pylon installations and high-lift devices.

Localisation of noise sources from the DLR microphone array measurements at ETW. Photo: © DLR/Embraer.

The optimised microphone array provided a high focus depth, which enabled precise three-dimensional localisation of aeroacoustic sources on the aircraft model. DLR developed new analysis routines featuring a deconvolution beamforming algorithm for the acoustic data evaluation on a spatially high-resolution 3D grid with about 1.3 million grid points. In addition, in order to improve the accuracy at lower frequencies a cross-spectral matrix fitting was applied. The results showed a detailed three-dimensional distribution of acoustic sources on the model. This enabled a highly accurate separation and allocation of acoustic sources on the model. A scientific publication detailing the acoustic measurements and the data processing is in preparation and will be presented soon.

Embraer flight test data compared with results extrapolated from ETW wind-tunnel data by DLR. Photo: © Embraer/DLR/ETW.

Subsequently, Embraer compared the results of the wind tunnel measurements with results from overflight measurements. The comparison of the third octave band results from the flight tests (red) showed a very good agreement to the results of the wind tunnel test (blue) especially for frequencies that would be perceived as disturbing and annoying.

The acoustic measurements in LoCaRe have shown that

- With little additional effort for the installation of a microphone array and corresponding data reduction, significant acoustical information can be gained in ETW piggyback to performance measurements at flight relevant take-off and landing conditions;

- The position and intensity of noise sources on the wings as well as on engine nacelles, slats and flaps can be measured;

- Acoustic testing can be performed for half- and also full-span models, both with solid and slotted test sections;

- The acoustic measurements showed a significant dependency on the Reynolds number. Hence, tests in ETW at high Reynolds numbers are very helpful to localise flight relevant noise sources within performance tests early in the design process. Further detailed investigations of these sources should be done with dedicated tools, e.g. DNW-LLF, DNW-NWB or DLR’s CAA tools;

- The results processed by DLR from ETW measured data and extrapolated to flight by Embraer agree well with full scale overflight measurements.

These investigations were carried out within the German LuFo V-3 project LoCaRe “Localisation and Characterisation of Flight Relevant Noise Sources on High Lift Systems” (Funding reference number 20A1701A).

Background

ETW - Pushes the Limits

Wind tunnels, using scaled down aircraft models, are the major source of aerodynamic design data for new aircraft projects. Wind tunnels are indispensable tools for aerodynamic research and aircraft development; they complement and validate flow simulation methods on the most powerful computers.

ETW, the European Transonic Wind Tunnel, was designed and constructed by the four European countries France, Germany, United Kingdom and The Netherlands. It is operated based on a non-profit policy by the ETW GmbH, founded in 1988. Its location in Cologne, Germany, is right in the middle of Europe.

European researchers and engineers harness ETW’s capabilities for advancing aeronautical science into aircraft innovation by accessing real-flight conditions in this cutting edge ground-test laboratory.

ETW is the worldwide leading wind tunnel for testing aircraft at real flight conditions. Aircraft performance and their flight envelope limits can be accurately determined with unique quality at ETW long before flight testing of a first prototype. This enables significant reductions in the technical and economic risks associated with the development of new aircraft. Manufacturers from all over the world take advantage of the exceptional features of this high-tech facility enhancing the performance, economic viability, and environmental friendliness of their future aircraft.

ETW – Erweitert Horizonte

Aerodynamische Entwurfsdaten für neue Flugzeugprojekte werden zu einem großen Teil aus Windkanaluntersuchungen an maßstäblich verkleinerten Flugzeugmodellen gewonnen. Windkanäle sind unverzichtbare Werkzeuge sowohl für die Strömungsforschung als auch für die Flugzeugentwicklung; sie ergänzen und validieren Verfahren zur Strömungssimulation auf modernsten Hochleistungsrechnern.

Der Europäische Transschall-Windkanal ETW ist eine transnationale Forschungseinrichtung in Köln. Er wurde von den vier Staaten Frankreich, Deutschland, Großbritannien und den Niederlanden entwickelt und gebaut. Betrieben wird er von der ETW GmbH, die als eigenständiges Non-Profit-Unternehmen 1988 gegründet wurde.

Der ETW erlaubt europäischen Forschenden und Ingenieur:innen, tatsächliche Flugzustände unter Laborbedingungen am Boden darzustellen, um wissenschaftliche Erkenntnisse zu erarbeiten und in Luftfahrtinnovationen zu überführen.

Der ETW ist der weltweit führende Windkanal, in dem Luftfahrzeuge unter wirklichkeitsgetreuen Flugbedingungen getestet werden können. Lange bevor der erste Prototyp für einen Flugtest zur Verfügung steht, können im ETW die Leistungsfähigkeit und die Flugbereichsgrenzen eines Neuentwurfs genauestens und mit einzigartiger Qualität bestimmt werden. Dies reduziert erheblich die technischen und wirtschaftlichen Risiken, die mit der Entwicklung neuer Luftfahrzeuge verbunden sind. Hersteller aus aller Welt nutzen die außergewöhnlichen Möglichkeiten dieser Hightech-Einrichtung, um die Leistungsfähigkeit, die Wirtschaftlichkeit und die Umweltfreundlichkeit ihrer zukünftigen Produkte nachhaltig zu verbessern.